This experience made him believe that the finest quality can only be delivered with uncompromising focus on details. While the Swiss luxury watch market was booming in the 1990s, he spent his savings to set LF – a one-man workshop in an industrial building equipped with a handful of machines specialised in making watch cases, taking orders outsourced by other factories. Each watch case was made with delicate craftsmanship, with the goal of creating an exquisite exterior that matches the intricate interior (the clockwork mechanism). Our dedication ultimately won clients over and we began to receive direct orders from the most renowned Swiss watch brands.

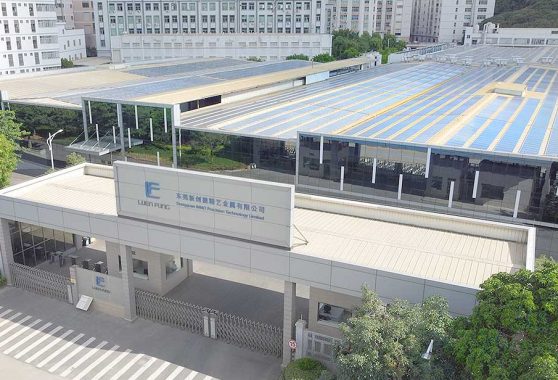

Throughout the years, we have continued to innovate and develop our technological capacity. This has enabled us to transform our production regime from a small-scale factory that produced handcrafted timepieces to a manufacturing powerhouse that fabricates precision metals for all kinds of high-tech devices.